Motor Balloon

I am building a hot air balloon with several propellers driven by small electric motors. The goal of this work is to create a better way to give hot air balloon rides to more people. The balloon envelope is complete and work on the bottom-end is currently underway.

Overview

One of my great joys is giving rides in small aircraft.

Giving hot air balloon rides Is particularly fun.

Hot air balloons typically fly for about an hour during the morning and evening hours when atmospheric conditions are most calm. One-hour rides are OK but not great. For passengers, the fun and wonder start to diminish after about 15 or 20 minutes. One-hour flights violate the First Law of Showbiz: Leave ’em beggin’ for more!

Rather than a single flight, I’d rather take several load of passengers on shorter rides. Doing that requires remaining above or very near the launch field. To accomplish this, I’m adding a set of small motor/propeller units to an otherwise conventional hot air balloon.

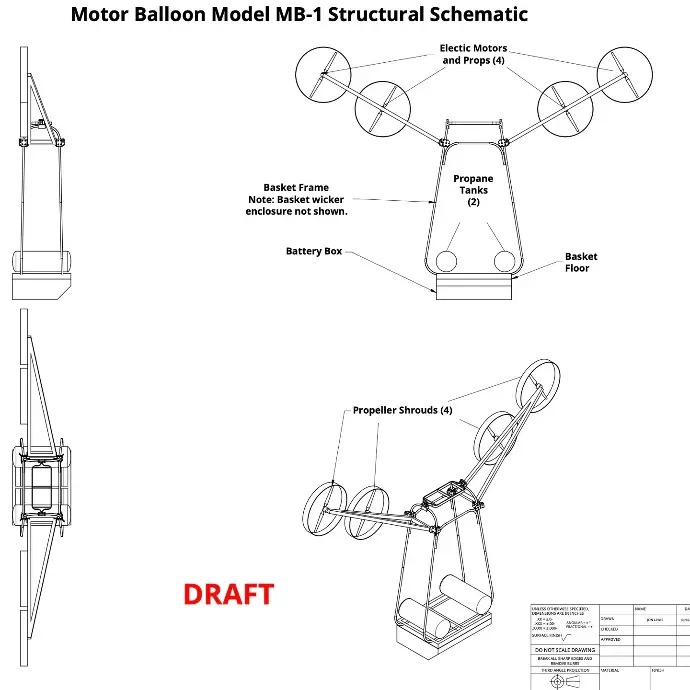

Schematic Drawing

Here is a structural schematic drawing of the bottom-end (a.k.a. the basket) of the aircraft

The “V1.0” configuration uses four 1-meter diameter (40 inch) propellers driven by electric motors to provide enough thrust to push the balloon around at something like 5 miles per hour. That should be enough airspeed to comfortably remain over or upwind of the launch field in very light winds.

The envelope (the big fabric bag) is a custom-built conventionally-shaped hot air balloon.

The bottom-end (for the people, fuel, etc.) is built around on a retired type-certified Aerostar wicker basket, burners, fuel tanks, etc. I am adding a battery box at the bottom and a pair of armatures to the left and right sides. Each armature will support two prop/motor units.

FAQ

Construction Status

With a lot of help from friends, I have a fully-built 140,000 cubic foot, conventionally shaped hot air balloon envelope.

The envelope had its initial inflation in September of 2023. That inflation test is shown in the photo to the right. Since then, I’ve been focused on designing and fabricating the components of each of the four novel aspects of the aircraft: the suspension system to support the added weight of the batteries, the battery box located below the basket, the arms on which the motors are mounted, and the shrouds around the props.

I hope to start flight testing in the Fall of 2025.

Photos from the Shop

Here are some photos of those components in progress.